Our products and services

Prefabrication of steel structures

Konstalex specialises in the manufacture of heavy steel constructions for the energy industry and for bridge structures.

In addition, we produce light constructions for general construction purposes, as well as specialised structures, both one-off and repeatable.

Our business includes the manufacture of steel structures:

road bridges, railway bridges, footbridges, viaducts

production and warehouse spaces

power plants

welded and bolted structures including machining

Manufacturing capabilities

Depending on the type of steel structure, the plant produces approx. 600 ÷ 1,000 tonnes of structures per month. Structures are manufactured from basic carbon and higher strength steel grades.

We carry out production tasks in the field of:

- plastic, thermal and mechanical processing as well as machining,

- welding of structures: gas welding (135, 136, 131), automatic welding machines (121), electrodes (111),

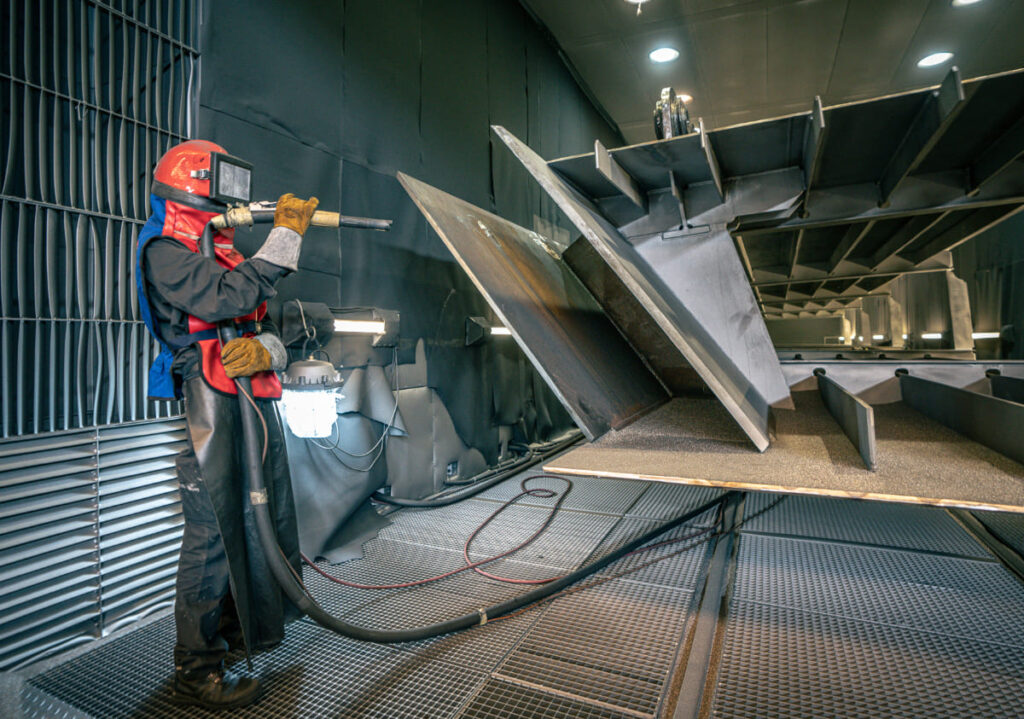

- corrosion protection: shot-blasting, painting with paint mixtures, thermal zinc spraying and thermal metal spraying.

Steel Constructions Manufacturing Plant in central Poland

Manufacturing plant in Radomsko

We have over 23,000 m² of production space, cranes with lifting capacities of up to 70 tonnes, and the ability to manufacture elements with dimensions of 4×5×40 m.

Our steel constructions manufacturing plant is equipped with specialised lifting equipment, modern cutting, welding and material-processing machinery, as well as equipment for carrying out measurements:

- CNC automatic machines for oxygen cutting,

- MAG C plasma for cutting and drilling sheet metal,

- the SCM 630 pipe shape cutting machine,

- CNC drill saw line for machining I-sections,

- FLOWDRILL tool for chipless thermal drilling and form tapping,

- automatic line for welding GRANGES I-sections made of sheet metal (submerged arc welding),

- automatic submerged arc welding machines,

- modern ESAB semi-automatic machines,

- UNION BFP 130 CNC drilling and milling machine

- bevelling planer with 3×15 m machining area,

- rollers for rolling metal sheets and sections,

- Laser tracker Omnitrac2 portable measuring device,

- IT-207A by Gränges automatic beam welding machine.

Transport

The steel construction plant is located in central Poland, with excellent access to expressways – the A1 and A2 motorways. The plant is located 5 km from the Warsaw-Katowice expressway.

The exit gates of the hall allow the transport of elements up to 5.8m wide.

Quality control and modern technologies

Product quality control

Quality control is carried out at each production stage, from the beginning of the manufacturing process to the acceptance of the finished product.

The plant is equipped with a laboratory with the possibility of conducting:

- non-destructive testing (NDT) of welds,

- linear and shape measurements of components,

- geodetic measurements of components, e.g. in trial assembly.

In cooperation with relevant institutions, it performs the following tests:

- chemical composition of metallurgical materials,

- destructive testing of welds.

Technological processes carried out in the plant

Basic technological processes

The plant’s operations are based on the following departments:

- preparatory,

- assembly and welding,

- anticorrosion coatings,

- auxiliary (energy, mechanical and tool shop).